- Production Machines

- Other Manufacturing Equipment

- Metal extrusion

- A.G.C. BUSINESS CONSULTING S.A.

- Products

- 188188金宝搏

- News & Trends

- Exhibitions

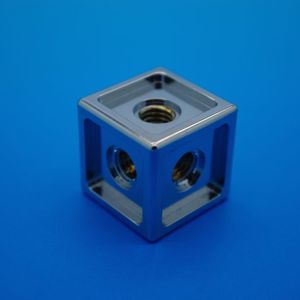

Metal extrusion

aluminum

添加到收藏夹”

Compare this product

Characteristics

- Type

- metal

- Material

- aluminum

Description

Extrusion process explained Extrusion is realized by pushing material through a fix die within a high pressure press. The output will be extrusion bars with a cross-sectional profile, shaped almost as a negative of the die or dies for complex shapes. Material is usually heated (around 400°C for aluminum) before entering the press in order to facilitate part shaping. Bars are usually extruded to 12m long, but longer or shorter ones may be available for specific usages. The parts extruded will have a constant cross-sectional shape all along its length. Heat treatment may be done after extrusion to remove stress from the profiles. Profiles finishing Next to the extrusion of the profiles, several additional operations can be conducted: – Cutting along the lenght of width of the profiles. – Drilling /thread drilling of holes along the profiles – Machining for complementary shapes that cannot be done by extrusion only. – Deburring – Surface treatment (mostly anodisation for aluminum)

Other A.G.C. BUSINESS CONSULTING S.A. products

Metal

Related Searches

- Stamping

- Metal stamping

- Die casting

- Aluminum die casting

- Open die stamping

- Automotive die casting

- 工业压铸

- Sand casting

- Extrusion

- Electronic die casting

- Railway sand casting

- Forging for the food industry

- Metal extrusion

- Aeronautic die casting

- Steel sand casting

- Aluminum extrusion

- Cast-iron die casting

- Stainless steel die casting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.